The Facilities Will Address This Gap, Enabling HAL To Manufacture Enough Critical Components To Support The Production Of Six LVM3 Rockets Per Year, It Said

ISRO Chairman Inaugurates HAL Facilities For Boosting Rocket Manufacturing

ISRO Chairman S Somnath inaugurated state-of-the-art propellant tank production and computer numerical control (CNC) machining facilities at Hindustan Aeronautics Limited’s Aerospace Division here, boosting rocket manufacturing capacity . HAL said the facilities would provide a major boost to ISRO’s ability to meet its growing production needs, particularly for the Launch Vehicle Mark-3, India’s heaviest and most powerful rocket.

HAL said the new facilities would address this gap and enable HAL to manufacture critical components to support the production of six LVM3s per year. The propellant tank production facility will specialise in the manufacturing of high-performance fuel and oxidiser tanks, critical components for the LVM3 4 m in diameter and up to 15 m in length. The CNC machining facility houses advanced computer numerical control machines for handling high-precision fabrication of 4.5 m-class rings and propellant tank domes of the launch vehicle.

Somnath said HAL was set to play a larger role in ISRO’s future missions and hence, should focus on emerging technologies, designing challenges, and take up end-to-end tasks to ease the pressure on ISRO.

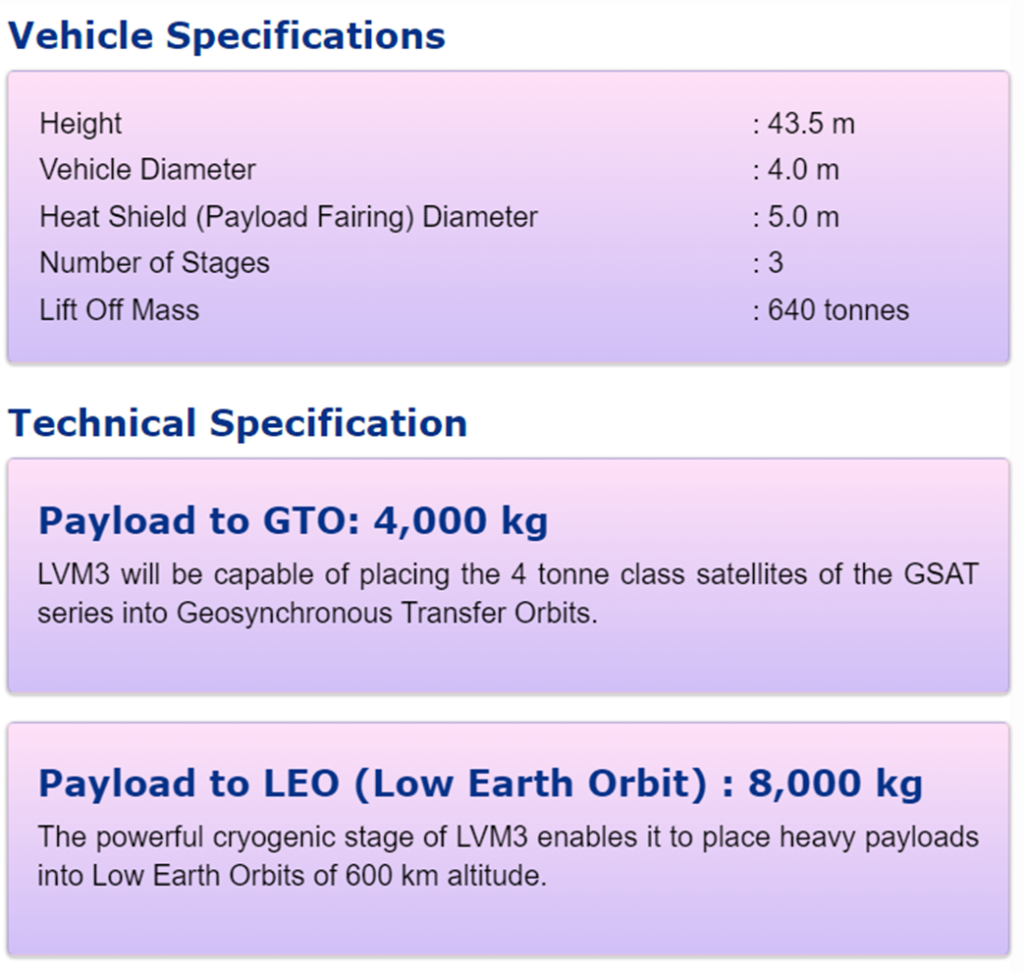

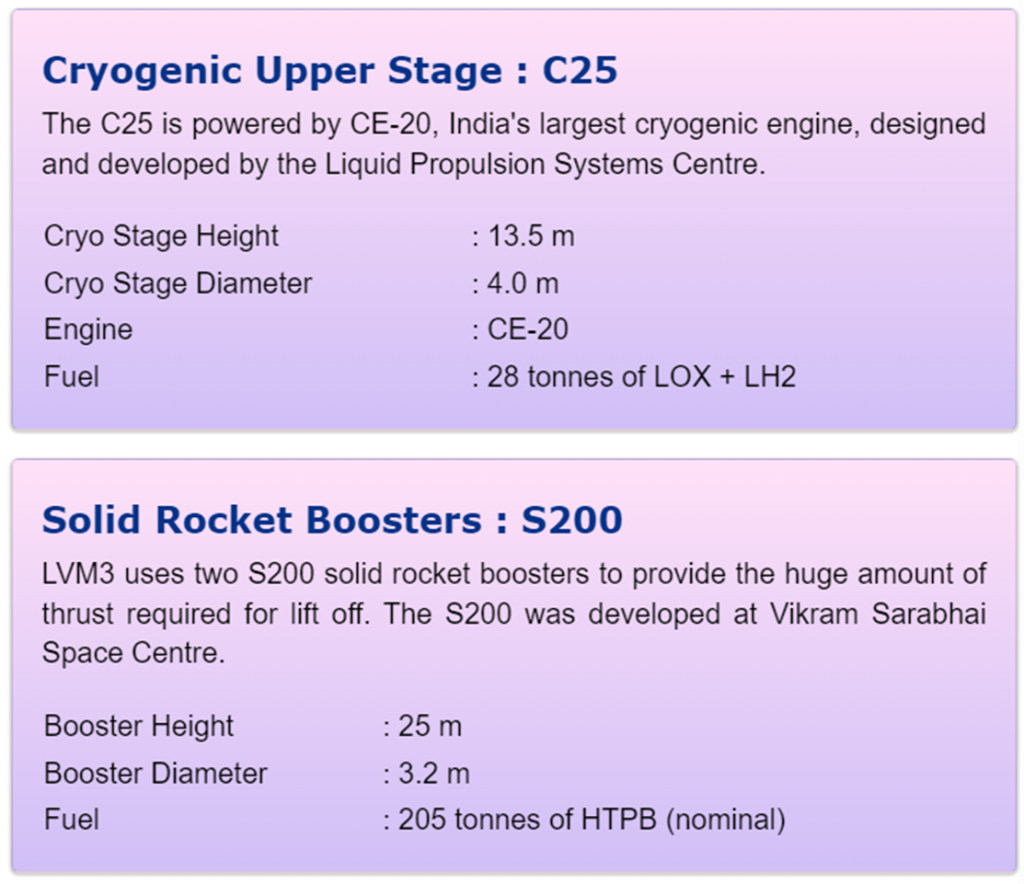

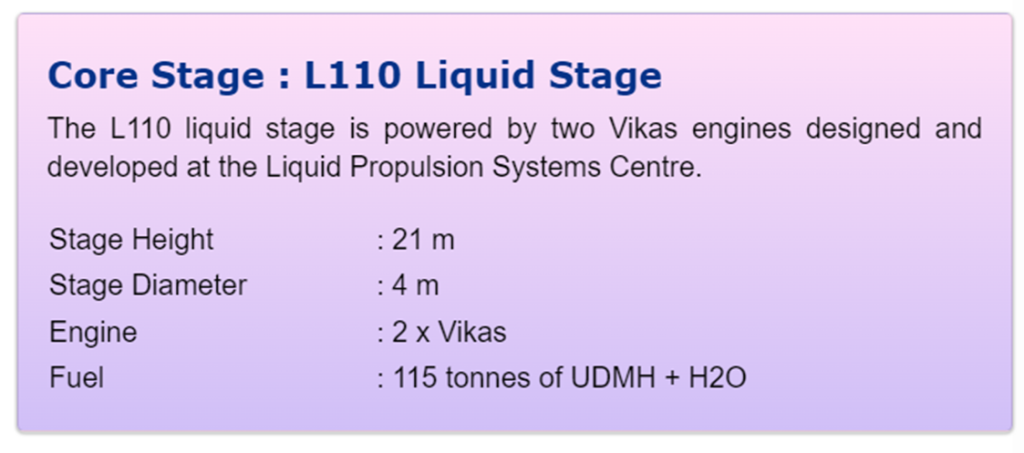

LVM3(Geosynchronous Satellite Launch Vehicle Mk III)

LVM3 is configured as a three-stage vehicle with two solid strap-on motors (S200), one liquid core stage (L110) and a high thrust cryogenic upper stage (C25). The S200 solid motor is among the largest solid boosters in the world with 204 tonnes of solid propellant. The liquid L110 stage uses a twin liquid engine configuration with 115 tonnes of liquid propellant, while the C25 Cryogenic upper stage is configured with the fully indigenous high thrust cryogenic engine (CE20) with a propellant loading of 28 tons. The overall length of the vehicle is 43.5 m with a gross lift-off weight of 640 tonnes and a 5m-diameter payload fairing.