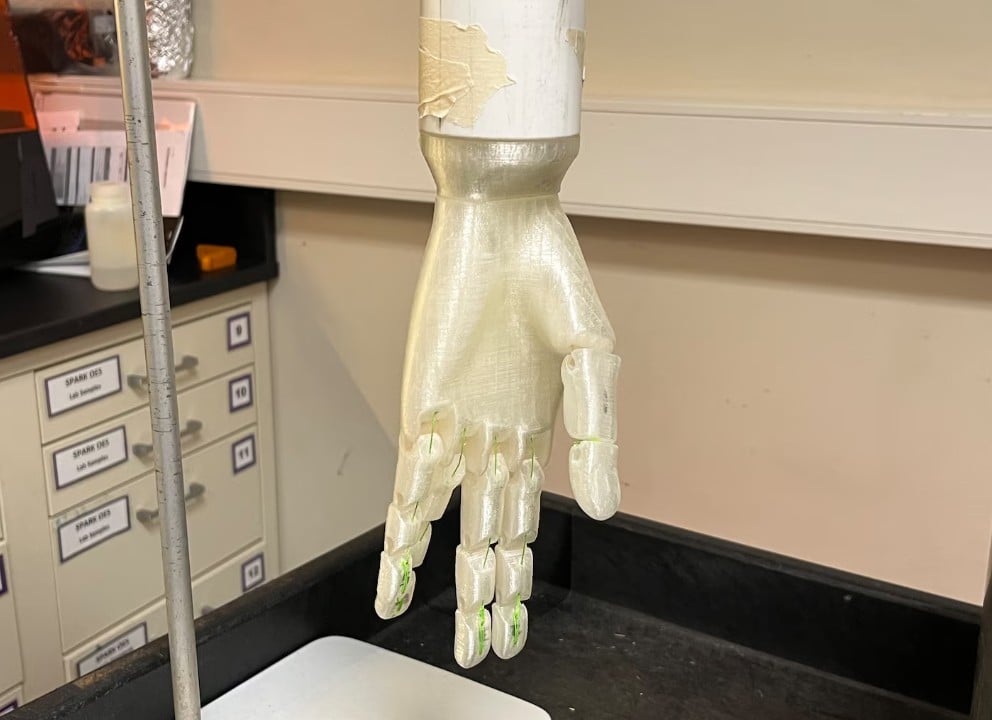

The US Defense Logistics Agency has introduced an innovative 3D-printed hand designed to enhance glove safety during military testing. This cutting-edge surrogate hand, crafted by the Product Test Center Analytical, is capable of flexing its fingers and can endure exposure to hazardous materials. This advancement allows researchers to assess the effectiveness of protective gloves without putting personnel at risk from substances like jet fuel.

Historically, testing procedures required human volunteers, leading to direct exposure and potential contamination from defective gloves. The new 3D model effectively removes this risk, significantly reduces the time needed for decontamination, and offers the flexibility to adjust to various glove sizes and finger lengths. This adaptability enhances the accuracy of safety assessments for military personnel.

Initial trials of the 3D-printed hand have been completed, and there are plans for further testing. The ultimate goal is to broaden the application of this technology to other types of protective gear, expanding its benefits beyond gloves.

In addition to this advancement, the US is actively promoting 3D printing technologies aimed at enhancing troop safety and combat readiness. In a recent collaboration, the US Army joined forces with the University of Hawaii to develop lab-grown tissues and organ-on-a-chip systems. This initiative seeks to translate bioprinting from the laboratory into real-world applications, potentially enabling rapid treatment with 3D-printed skin and other tissue models in remote or high-risk environments.

Researchers involved in this effort highlight that the technology has dual purposes. It not only aids in understanding bodily responses to chemical and biological threats but also has the potential to lead to deployable, life-saving medical tools.

Additionally, efforts at the Rock Island Arsenal Joint Manufacturing and Technology Center aim to ramp up the production of 3D-printed drones for the US Army. This program involves placing new drone systems directly into operational settings for field testing. Feedback from soldiers plays a crucial role in shaping technical requirements and guiding future production, ensuring that the technology evolves in line with real-world needs.