In a significant advancement for military technology, researchers at the Purdue Applied Research Institute (PARI) are pioneering the use of 3D-printed dark ceramics for America’s hypersonic missiles and aircraft. This innovative approach aims to enhance the durability and performance of hypersonic vehicles, which are designed to travel at speeds exceeding Mach 5, placing them under extreme conditions.

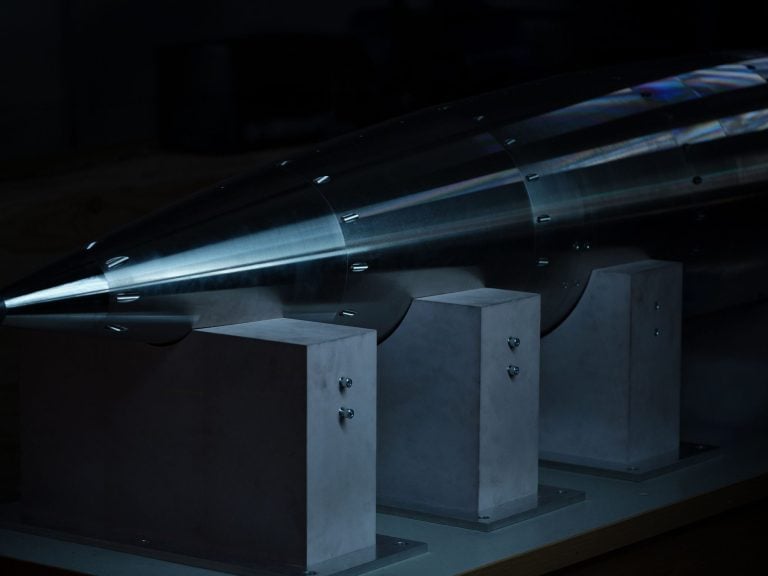

The research team is utilizing digital light processing (DLP) 3D printers to manufacture these dark ceramics in precise shapes and sizes, achieving high-resolution surfaces. Project lead Rodney Trice emphasized the potential of this technology, stating, “This allows you to produce intricate designs and geometries with very smooth surfaces and with a level of precision at the micron level.” The ability to create complex components like sharp cones and hemispheres can significantly contribute to the structural integrity and aerodynamics of hypersonic vehicles.

This initiative builds upon previous efforts by the U.S. military to explore additive manufacturing technologies for hypersonic systems. In May 2024, the Pentagon had already contracted Aerojet Rocketdyne to develop a 3D-printed hypersonic propulsion prototype, demonstrating a broader commitment to integrating advanced manufacturing techniques into defense capabilities.

However, the team faces specific challenges associated with the properties of dark ceramics. While their inherent resistance to extreme conditions makes them suitable for hypersonic applications, their color poses obstacles for the DLP-based printing process. The dark pigments in these ceramics absorb ultraviolet (UV) light, which is critical for curing the material. This absorption not only disrupts the curing process but also lengthens production times due to the inability to form thick layers. Trice noted, “Because dark powders absorb the UV light … we cannot form as thick of a layer. Therefore, we get cure depths that are too thin, which then negatively impacts the time it takes to build each part.”

To address these hurdles, the PARI team plans to collaborate with experts in materials science to explore various resin systems, surface treatments, and innovative methodologies. These collaborative efforts are essential for streamlining post-processing phases and enhancing the overall efficiency of the 3D printing process.

As developments continue, the incorporation of advanced materials like dark ceramics could revolutionize the capabilities of hypersonic technology, positioning the U.S. on the cutting edge of military innovation.