Firehawk Aerospace has announced a strategic investment from Hanwha Defense USA aimed at accelerating the development of its solid rocket motor technology. This initiative focuses on enhancing production and system integration, harnessing Firehawk’s advanced additive manufacturing capabilities along with its patented processes.

The investment is set to expedite the large-scale production of 3D-printed propellant, facilitating motor development and the integration of complete missile systems. Will Edwards, CEO of Firehawk, emphasized that this funding aligns with the company’s mission to modernize solid rocket motor technology, addressing the limitations posed by the existing industrial supply chain while delivering a significant advantage to military operatives.

Firehawk asserts that by scaling additive manufacturing practices, constraints typically linked to conventional propellant manufacturing processes can be mitigated. The result is a more efficient, safer, and cost-effective method for producing customized munitions, all within a reduced facility footprint.

Mike Smith, COO of Hanwha Defense USA, highlighted the innovative nature of Firehawk’s production strategy, noting that it transforms the possibilities within the propulsion industry.

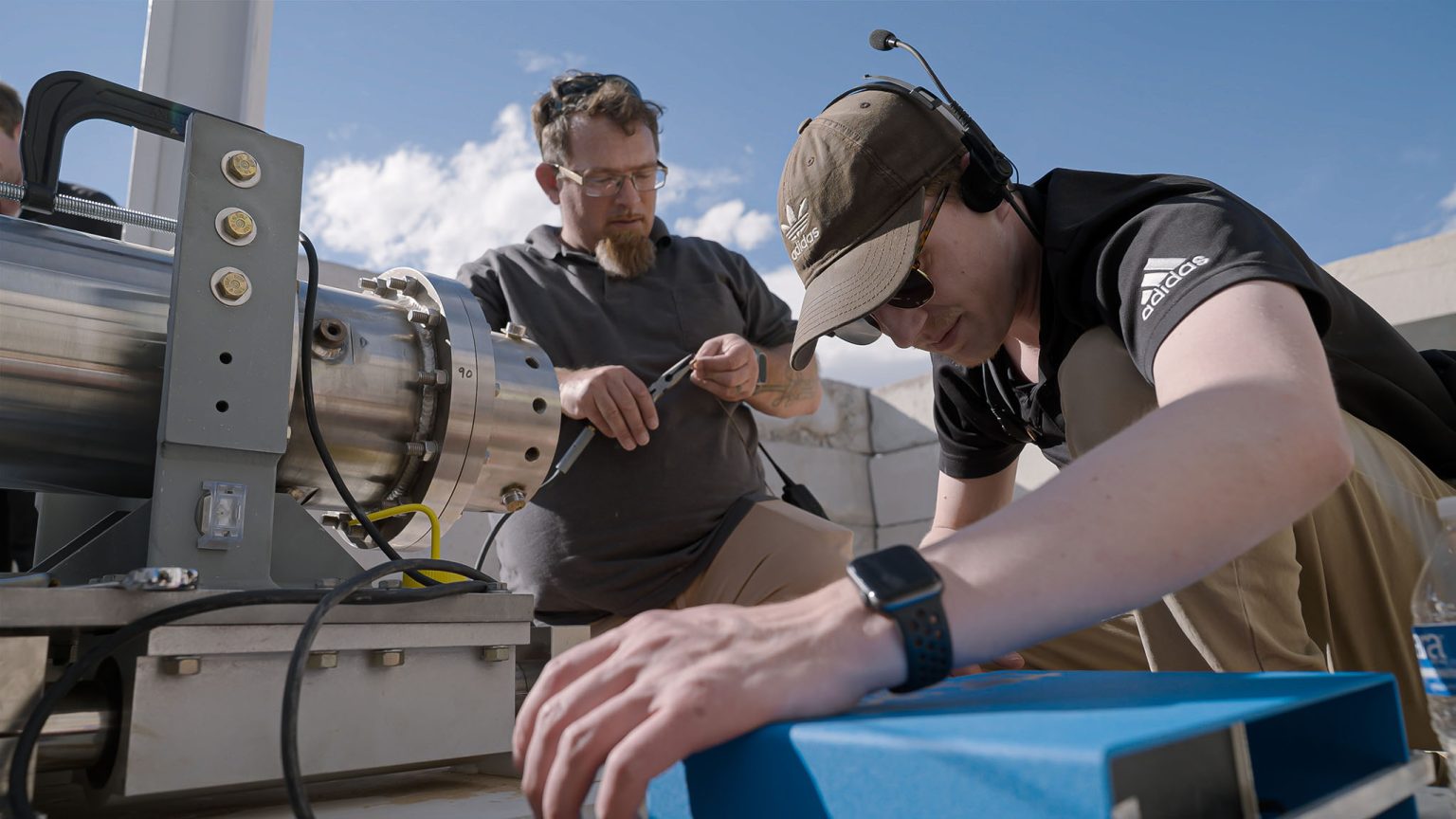

Firehawk, based in the United States with operational facilities in Texas and a manufacturing site in Lawton, Oklahoma, is engaged in various projects aimed at modernizing rocket systems through 3D printing and additive manufacturing techniques. Recently, the company secured a $4 million contract from the US Air Force to develop new thermoplastic-based, 3D-printed solid rocket propellants designed to enhance missile range, under a joint initiative involving the Air Force Research Laboratory and SpaceWERX. Earlier this year, Firehawk also successfully completed a supersonic test flight of its hybrid 3D-printed rocket engine, Firehawk Analog, which reached an altitude of 18,000 feet (5,486 meters) from a mobile launch platform.