In a significant advancement for the US Air Force’s Next-Generation Adaptive Propulsion (NGAP) program, GE Aerospace and Pratt & Whitney have successfully completed the detailed design review of their proposed engine technologies. This milestone marks the fourth stage in the six-phase development process, which has previously included initial design, preliminary design, and adaptive prototyping planning. The completion of this phase enables both companies to begin the procurement, assembly, and testing of prototype ground demonstrators, with operational testing anticipated in the late 2020s.

Recently, each company received contract upgrades valued at $3.5 billion for the prototyping phase, reflecting the importance and potential impact of their contributions to the program. Both GE Aerospace and Pratt & Whitney have integrated extensive digital tools throughout their design processes, employing advanced modeling and simulation technologies to refine their engine designs.

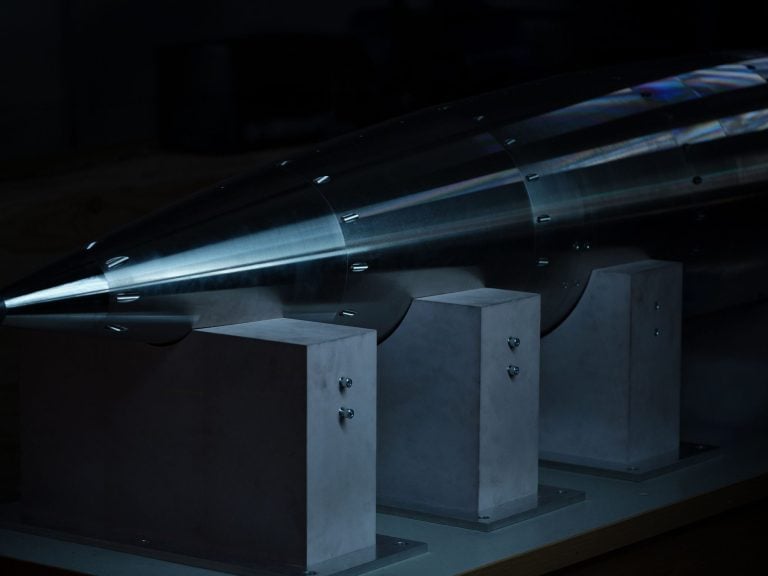

GE’s upcoming prototype, designated XA102, promises to be notably innovative, as it will be the first engine developed utilizing model-based systems engineering, heralded as a transformative leap in the industry’s approach to engine design. Steve Russell, vice president and general manager of Edison Works at GE Aerospace, emphasized the importance of this strategy, indicating a commitment to integrating innovative methods while collaborating closely with supply chain partners during the upcoming procurement and production phases.

Pratt & Whitney’s Military Engines division, led by president Jill Albertelli, highlighted the pivotal role of digital tools and processes in the maturation of their technology. She noted that the advancements demonstrated by their NGAP team will lay the groundwork for future generations of solutions aimed at enhancing airpower capabilities.

At the core of the NGAP initiative is the adaptive cycle engine technology, which is designed to power the US Air Force’s Next-Generation Air Dominance fighter jet. This new engine configuration provides not only high thrust but also improved fuel efficiency, addressing the critical need for versatility in modern air combat scenarios. Unlike traditional fixed cycle engines, which are optimized for either high thrust or fuel efficiency, the adaptive cycle engine introduces a third stream of airflow that can be activated to enhance cruise efficiency or retracted during phases requiring maximum thrust, such as takeoff, landing, and combat operations.

According to GE, their proposed engine offering will achieve a remarkable 20 percent increase in thrust while simultaneously enhancing fuel consumption by 25 percent, leading to an overall range increase of 30 percent. Furthermore, these adaptive cycle engines are anticipated to better manage engine heat, generate increased electrical power essential for advanced avionics, and support next-generation armament such as laser weapons, positioning the US Air Force for continued superiority in aerial engagements.