Velo3D has entered into a significant agreement with the US Defense Innovation Unit (DIU) aimed at enhancing additive manufacturing processes. This partnership is set to facilitate faster component production, enhance consistency, and provide scalable output to meet the dynamic needs of the defense sector. The agreement is valued at $32.6 million and falls under DIU’s Project FORGE initiative, which is designed to tackle production bottlenecks that hinder the output of critical defense systems.

As part of this collaboration, Velo3D will engage with DIU, the US Navy, and a prime contractor to prototype and qualify additively manufactured components that can either replace or augment existing parts in defense systems. This effort underscores the growing need for innovation in manufacturing techniques to maintain operational readiness within the defense industry.

Additionally, the contract includes an option to evaluate large-format laser powder bed fusion capabilities within the United States. This aspect of the agreement is particularly vital as it is intended to address manufacturing needs that are not currently fulfilled by the domestic industrial base, thereby enhancing local production capabilities.

Velo3D has emphasized that its manufacturing systems comply with the cybersecurity standards set by the US Department of Defense. The systems are engineered for secure connectivity with military networks, ensuring the protection of sensitive data and the integrity of production processes. This compliance is crucial for maintaining the security and reliability of defense-related components.

The company plans to implement its Rapid Production Solution, which combines metal additive manufacturing systems, support for production, and surge capacity. This approach aims to expedite the development and qualification of 3D-printed components tailored for defense applications.

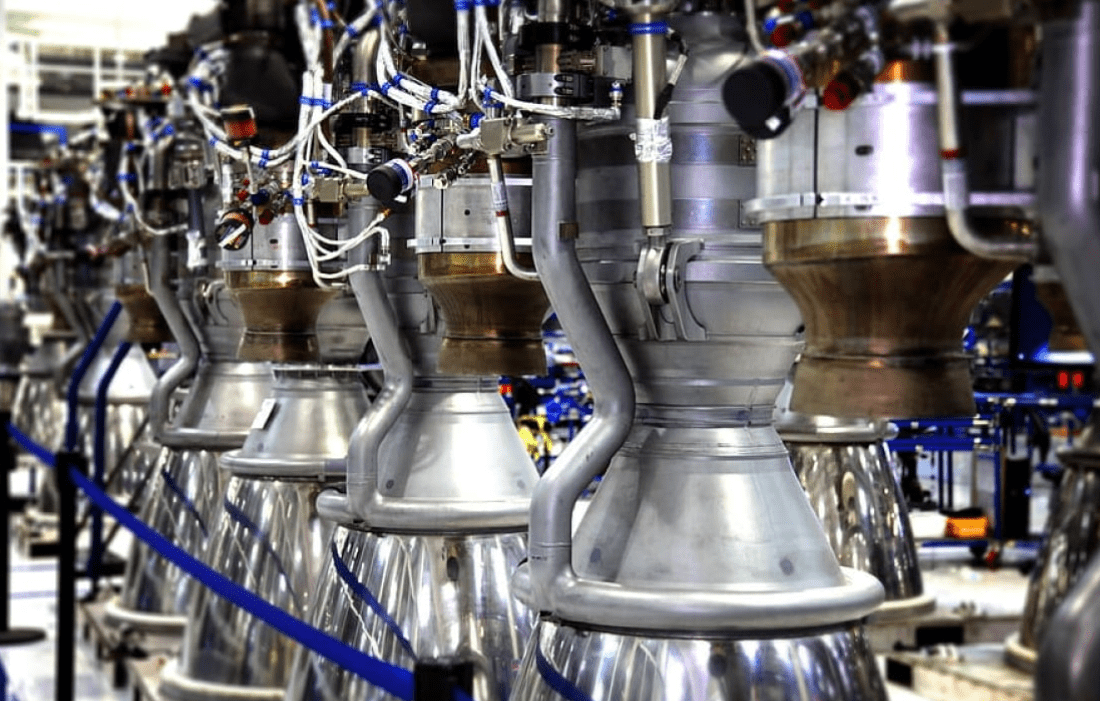

Velo3D will utilize its US-assembled Sapphire printers for this initiative, which are capable of producing metal components with dimensions of up to 600 millimeters in diameter and one meter in height. The printers employ advanced laser powder bed fusion technology and feature in-process monitoring capabilities to ensure consistent quality and reliability throughout the production cycle.

This partnership marks a strategic move to bolster the US’s defense manufacturing capacity through innovative additive manufacturing solutions.