In a significant development for defense technology, Firehawk Aerospace has secured a $4-million contract from the US Air Force to pioneer the production of 3D-printed solid rocket propellant. This innovative approach aims to enhance missile range capabilities, representing a crucial advancement in military weaponry.

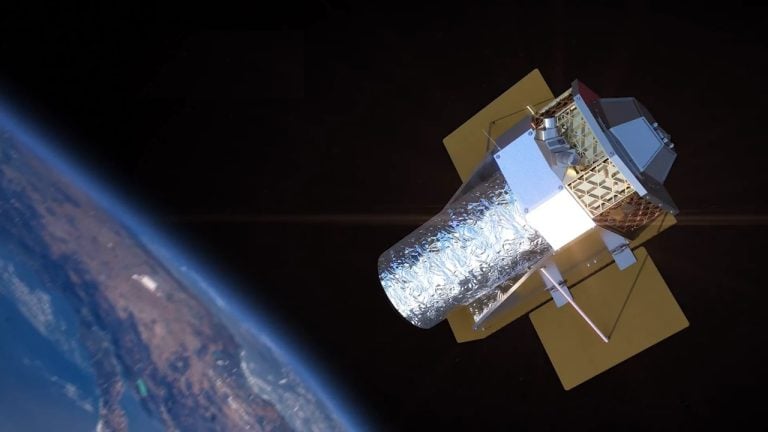

Firehawk is focusing on thermoplastic-based propellants, marking a shift from traditional solid rocket fuels. This initiative is part of a collaborative effort supported by the Air Force Research Laboratory and SpaceWERX, the innovation arm of the US Space Force. The company asserts that its additive manufacturing techniques will lead to safer, more versatile, and higher-performing rocket propulsion systems.

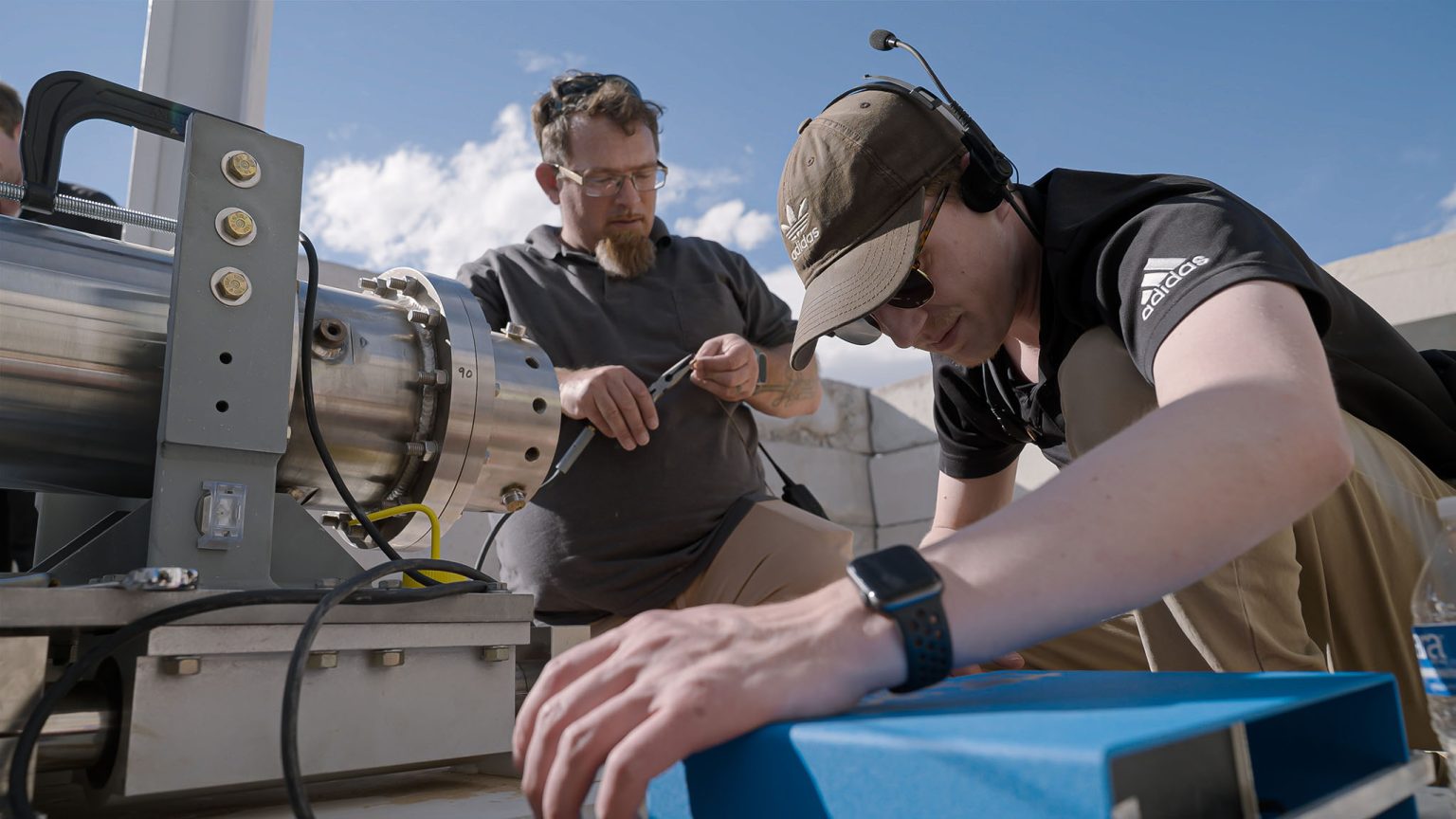

Traditional methods of rocket production are known for being labor-intensive and characterized by lengthy lead times. In contrast, 3D printing allows for rapid prototyping, intricate designs, and improvements in overall performance. Will Edwards, CEO of Firehawk, emphasized that the company is committed to addressing the operational needs of today’s forces, as well as preparing for future challenges, ultimately ensuring that warfighters possess a competitive edge.

The funding for this initiative comes through the Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs. These programs are designed to energize innovation by providing financial support to small businesses exploring a wide array of technologies with potential applications in defense.

Firehawk Aerospace is emblematic of a fresh wave of agile suppliers capable of moving quickly from conceptualization to demonstration—an approach that starkly contrasts the lengthy timelines often associated with traditional defense contractors. This funding underscores a broader push to incorporate advanced manufacturing techniques into defense systems that require both speed and reliability, ensuring that US forces retain operational flexibility and reach in contentious environments.

In a related vein, the US Army recently unveiled its own initiatives leveraging 3D printing to swiftly produce essential components without dependence on distant factories. This emerging technology has already been utilized to support maintenance for tactical platforms, including infantry squad vehicles and M777 lightweight 155-millimeter howitzers, further illustrating the military’s commitment to innovation in its operational strategies.