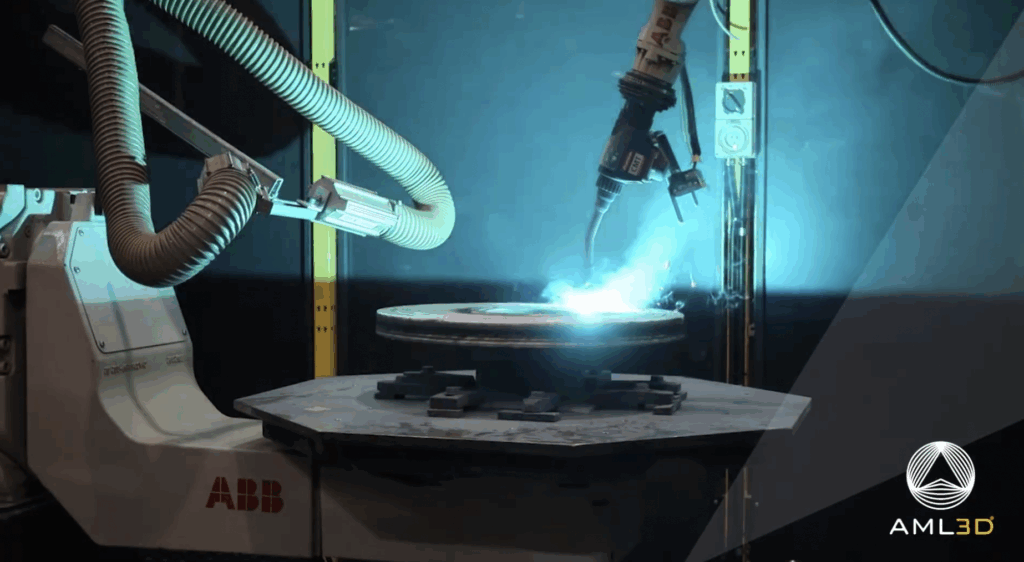

HII Newport News Shipbuilding has announced the acquisition of two state-of-the-art metal 3D-printing systems from additive manufacturer AML3D, marking a significant investment of 4.5 million Australian dollars (approximately $2.9 million). These advanced systems are specifically designed for HII, the largest military shipbuilder in the United States, and will utilize AML3D’s innovative ARCEMY X platform.

Equipped with a robust 10,886-kilogram (24,000 pounds) positioner, the new systems are intended to cater to the demands of heavy-capacity builds, allowing for the production of large and intricate metal components essential for ships and submarines. Once operational in mid-2026, the systems are expected to significantly reduce lead times and minimize material waste when compared to traditional manufacturing techniques.

This order marks the ninth and tenth ARCEMY systems incorporated to support the U.S. Navy Maritime Industrial Base. The cutting-edge technology employed in these systems is designed to produce high-strength, corrosion-resistant metal parts with greater efficiency and a lower environmental footprint.

Sean Ebert, CEO of AML3D, highlighted the substantial opportunity for the company to deepen its roots in U.S. Navy shipbuilding and munitions sectors. As the adoption of 3D-printing technologies gains momentum among U.S. defense contractors, the Navy is focused on modernizing its maintenance and production processes. This initiative aligns with the Pentagon’s broader strategy to enhance supply chain resilience while also shortening production timelines for vital systems.

Both HII and General Dynamics Electric Boat have begun integrating metal additive manufacturing into their submarine and surface ship programs. They have successfully produced various components for the Virginia- and Columbia-class submarines, showcasing the practicality and effectiveness of this technology.

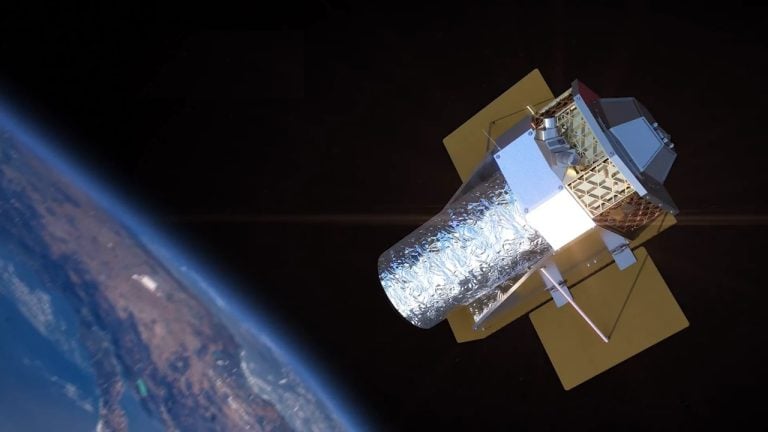

Further reinforcing the military’s shift toward 3D printing, the U.S. Navy introduced new systems in August aimed at transforming battlefield logistics. This technology facilitates on-site production of essential components, lessening reliance on lengthy supply chains. Developed in collaboration with the U.S. Marine Corps, the systems can fabricate a wide range of items, from small fittings to substantial titanium parts, with the added capability for resupply via drones or unmanned surface vessels. This innovative approach promises to enhance operational efficiency and agility in the field.