Parts from retired Royal Air Force Tornado jets have been reimagined as integral components for the UK’s next-generation military aircraft through an innovative recycling initiative. This project focuses on converting components with high titanium content—such as jet engine compressor blades—into new, functional parts utilizing advanced 3D printing technology.

The process began by cleaning and repurposing the retired aircraft parts. Additive Manufacturing Solutions (AMS) took the lead in transforming these materials into 3D-printed components, including compressor blades and a nose cone, which were subsequently fitted onto the Orpheus small engine concept. The capabilities of these recycled components have already been validated as Rolls-Royce conducted tests confirming their suitability and safety for future applications.

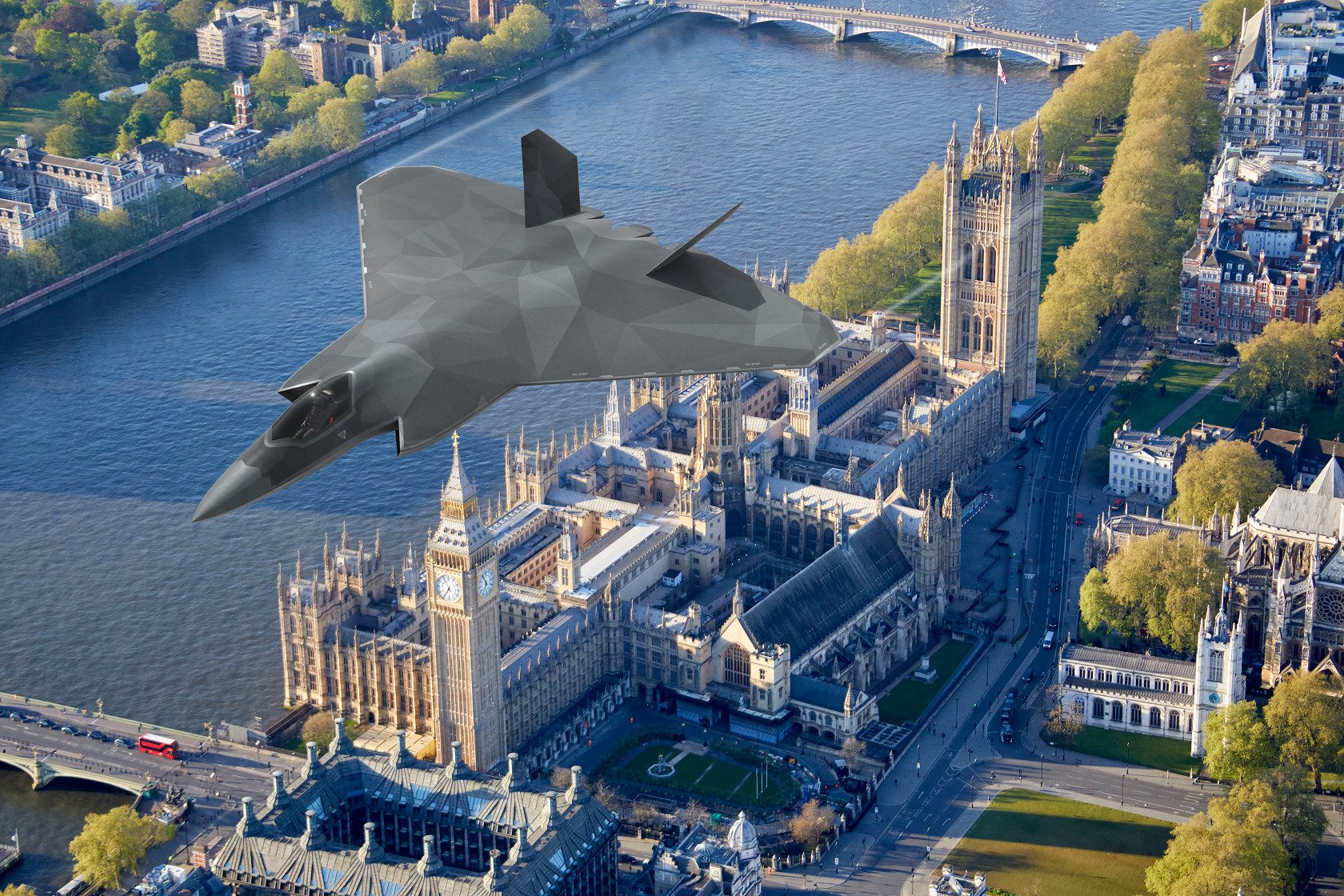

Minister for Defence Procurement and Industry, Maria Eagle, highlighted the significance of the Tornado 2 Tempest project in showcasing the UK’s creativity and innovation in national security strategy. She emphasized that collaboration with key industry partners will not only yield cost savings but also mitigate dependence on global supply chains. With these advancements, the ministry aims to equip the Armed Forces with superior technology essential for national defense.

The initiative not only addresses environmental sustainability by recycling old military assets but also aims to bolster the domestic defense industry. The Ministry of Defence is keen on using this approach as a central feature of its broader Plan for Change, which seeks to modernize and enhance the UK’s defense capabilities.

The project is expanding its horizons, as additional surplus military assets that contain valuable materials such as high-quality steel, aluminum, and titanium are being identified for potential recycling. According to the UK Ministry of Defence, this initiative promises to save taxpayer money while delivering products of higher quality than those produced using traditional forging techniques.

The Defence Equipment and Support’s Defence Recycling & Disposals Team is spearheading this project in partnership with the MoD’s Future Combat Air System (FCAS) team, Rolls-Royce, and AMS based in Lancashire. Robert Higham, AMS Director, remarked on the importance of innovative solutions for establishing a sustainable future. He noted the satisfaction his team felt when turning their ideas into practical outcomes, and expressed gratitude towards the MoD and Rolls-Royce for granting them the opportunity to demonstrate their capabilities in enabling circular economy processes within the defense sector.

Overall, this initiative represents a meaningful stride towards enhancing the UK’s military technology while fostering environmental responsibility and economic efficiency.