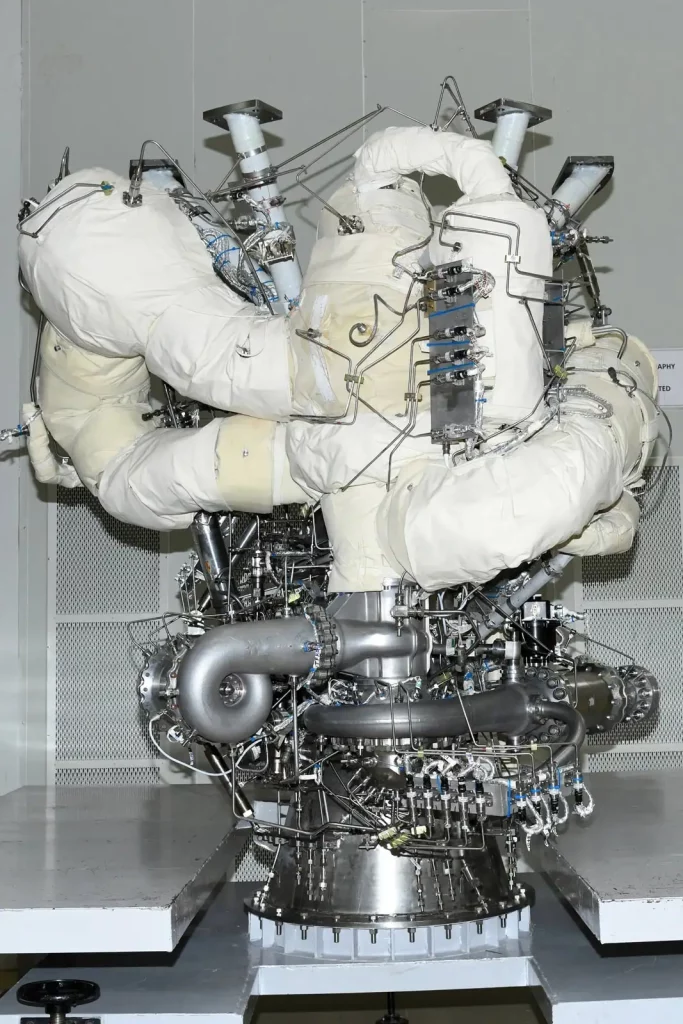

The Liquid Propulsion Systems Centre, a part of the Indian Space Research Organisation (ISRO), created the CE-20 cryogenic rocket engine. It was designed to power the LVM-3’s higher stage. It is India’s first cryogenic engine with a gas-generator cycle. The high-thrust cryogenic engine is the world’s most powerful upper-stage cryogenic engine currently in operation.

ISRO’s Semi-Cryogenic Engine

The SCE-200 (Semi-Cryogenic Engine-200) is a 2 MN thrust class liquid rocket engine being developed by India to power future heavy and super heavy-lift launch vehicles. It is being developed by ISRO’s Liquid Propulsion Systems Centre and is scheduled to fly in a few years.

The engine, which burns liquid oxygen (LOX) and RP-1 kerosene in an oxidizer-rich staged combustion cycle, will increase the payload capacity of India’s existing LVM-3 by replacing the present L110 stage powered by two Vikas engines. It will also power ISRO’s next New Generation Launch Vehicle (NGLV) rockets (formerly planned as ULV) as well as future reusable rockets based on the RLV technology demonstrator.

About Cryogenic Engines

Cryogenics is the study of materials’ formation and behaviour at very low or very low temperatures. The Cryogenic Engine is propelled by liquid hydrogen and liquid oxygen. Cryogenic engines have some drawbacks: the usage of liquid hydrogen at extremely low temperatures is difficult to store because it is the lightest element. The expense of producing and utilising liquid hydrogen is too expensive. Instead of liquid hydrogen, a semi-cryogenic engine runs on refined kerosene. It employs liquid oxygen as an oxidant.

CNG (Compressed Natural Gas) can also be used as a fuel. The Semi-Cryogenic engine will be employed in the Gaganyaan Human Spaceflight project, in addition to ordinary ‘application’ flights.

Advantages of Semi-Cryogenic Engine

- Kerosene is significantly lighter than liquid fuel and may be kept at room temperature.

- The combination of kerosene and liquid oxygen gives the rocket extra thrust.

- It also takes up less space, allowing for more propellant to be stored in the fuel compartment or tank.

- In comparison to a cryogenic engine, a semi-cryogenic engine is more environmentally friendly, cost-effective, and powerful.

- It can transport a large amount of weight to a greater altitude.

- The payload can be increased because the fuel weight will be reduced by 500kg.

The first integrated test on an intermediate configuration of the 2000 kN Semi cryogenic-Engine was performed on May 10, 2023, at the Semi Cryogenic Integrated Engine & Stage Test facility in IPRC, Mahendragiri. Complex chill-down operations were carried out during the 15-hour test to meet the requirements for engine start.

To crack the SSB Interview and join the Indian Army as an Officer, You can join our SSB interview live classes batch and we recommend you to Enroll SSB INTERVIEW ONLINE COURSE. Trusted by thousands of defence aspirants.

Also read:

- ISRO Aims To Launch Quantum Tech Satellite

- ISRO And NASA To Launch A Joint Mission To Space In 2024

- ISRO To Launch Ambitious Chandrayaan-3 Moon Mission In July

- About ISRO’s Inflatable Aerodynamic Decelerator (IAD)

- ISRO Successfully Conducts Autonomous Landing Of India’s First Reusable Rocket

- Complete List Of ISRO Launchers [Must Watch]

- Top 7 Rockets Launchers By ISRO [Fully Explained]

- 500+ ISRO Related GK Questions For All Defence Exams And SSB Interviews

- 14 Inspiring Achievements Of ISRO