The much-awaited India-US jet engine technology transfer agreement is likely to be signed soon, with the engines being produced “within three years.” The agreement calls for the production of a 110 KN (kilonewton) engine in India. “We are ready to sign the agreement soon, and India will have this engine within three years,” claimed a senior Ministry of Defence official.

India-US Jet Engine Programme

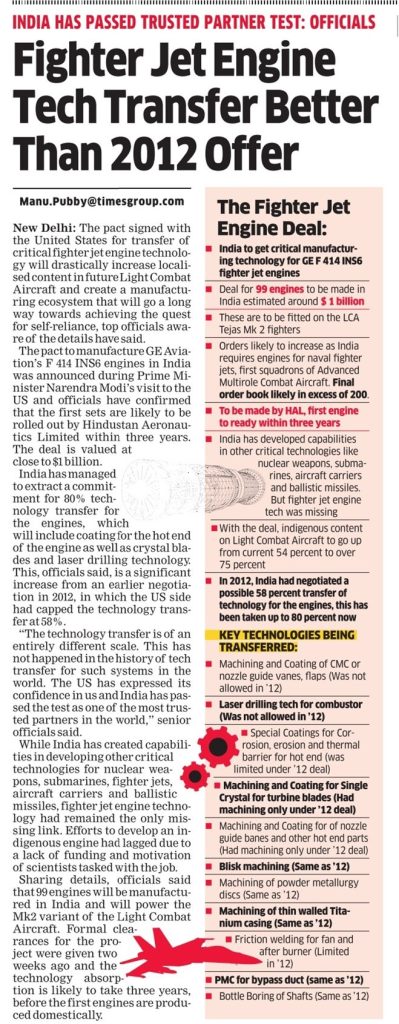

While the project’s cost has yet to be determined, sources estimate that the number of engines to be co-produced will be approximately 100, however, the Indian Air Force has not specified an exact number. The acquisition is crucial since India lacks engine-related expertise, and it will be desired even more in the future as the Air Force is now down to roughly 30 combat squadrons as opposed to a sanctioned strength of 42. While the GE-F414 engines are being installed in the TEJAS MK-2, work is also being done on twin-engine deck-based fighters and advanced medium combat aircraft (AMCA).

According to a senior MoD official, the significance of the GE-HAL deal for the 414 engine is that India will have access to cutting-edge technologies. “India did have some success in obtaining important technologies from Russia, the United Kingdom, and France.” However, the GE-F414 transaction is on a different level and size. It is unmatched in India’s history of high-tech pursuit.”

Nuclear power, jet engines, submarine construction, aircraft carriers, and ballistic missiles are examples of vital military technologies. “We obtained some of these through the hard work of our scientists and political initiatives,” sources claimed. According to the sources, this transaction demonstrates the level of trust India has earned among the highest levels of the US government, as seen by the fact that it gained bipartisan backing.

“Through this agreement, we will receive an 80% transfer of technology in the manufacture of the GE-F414 engine, which will improve the operational performance of the TEJAS MK-2.” Except for minor components, up to 80% of the engine will be manufactured in India. According to defence analysts, India will be among the top five countries to have this technology.

Also read: What Is LCA Tejas Mark 2 Project? [Fully Explained]

Special corrosion coatings, machining and coating for single crystal for turbine blades, machining and coating of nozzle guide vanes, Blisk machining, machining of powder metallurgy discs, machining of thin-walled titanium casing, laser drilling technology for the combustor, and many other critical technologies will be available to India under the agreement.

Cutting-Edge Technologies to Come Home

- Special coatings for corrosion

- Casting, machining and coating for single crystal turbine blades

- Casting, machining and coating of nozzle guide vanes and other hot parts

- Blisk machining

- Forging and power metallurgy discs for turbines

- Machining of thin-walled titanium casing

- Friction inertia welding for fan and after-burner

- Polymer Matrix Composites (PMC) for bypass polymer duct

- Ceramic Matrix Composites (CMC) for LPNGV, flaps, etc

- Laser drilling technology for combustor

- Critical tech for internal components

To crack the SSB Interview and join the Indian Army as an Officer, You can join our SSB interview live classes batch and we recommend you to Enroll SSB INTERVIEW ONLINE COURSE. Trusted by thousands of defence aspirants.